The aim of a circular economy in the footwear market seems implausible when taking into account the approximate 22 billion shoes that are sent to landfills each year. When it comes to recycling, footwear can be particularly troublesome considering that shoes can contain up to 40 differing materials that are virtually impossible to separate. Bound together by an assortment of glues and chemicals, it’s clear that footwear originally wasn’t made to be recycled. In fact, certain soles can last up to 1,000 years in landfill. There’s no more time left to waste, adapting to a circular economy is a must.

Is there any Hope for a Sustainable Future in Footwear?

Imagine being able to purchase a shoe free from harsh chemicals and glues, designed to unique perfection and made to be reborn at the end of its life. A shoe with the ability to propel you forward, enhance your athletic ability and provide you with unmatched support. We’re often told that if it’s “too good to be true, it probably is”. Not in this case.

3D Printed Footwear: The Promising Future

3D printing originated in 1981 from the great mind of Dr. Hideo Kodama, but it wasn’t until 2010 that this technology hit the fashion industry when Iris Van Herpen became the first designer to present 3D printed couture down the runway. Three years later, Nike is said to be the first to use 3D printing technology to craft soccer shoes. Since then, it’s been a race against time to patent a shoe that is 100% eco-friendly with early adopters such as Adidas, Reebok and New Balance jumping on board to revolutionise the market. 3D printing is majorly streamlining the design process, bringing designers closer to “perfection”, given the freedom to make an abundance of iterations without doing harm to the environment, making it an all-round favourable mode of production. It’s an exciting time for athletes with 3D printers providing an intricate, irreplicable lattice that drastically enhances performance. For these reasons, it’s understandable why the major players in footwear are making use of this revolutionary technology. Like anything, however, there are a few limitations. For those using 3D printing, there’s a vital responsibility to source sustainable materials as not all 3D printing materials meet the criteria to be biodegradable or recyclable. Chemicals used in certain printing processes are also in question, raising concerns about prolonged contact with skin.

Among the well known brands reshaping the industry, are some incredible projects set to shift the future of footwear. Servati is a start-up based in Italy, founded by economics graduate Matteo Di Paola, and Marco Primiceri, a design and visual communication graduate. Miracle workers, the pair have joined forces to produce sneakers that are free from glues, chemical solvents and heat-activated adhesives. Composed of only rubber and polyester materials, the entire shoe can be disassembled and repurposed, contributing to a circular economy. With the planet and well-being of all life at front of mind, Matteo and Marco spend months on end researching in order to select materials that are 100% recyclable. With their second drop scheduled for Monday March 11, the roadmap to a circular economy is crystallising.

The team at Vivobarefoot are another force paving the way for design processes of the future. With their project “VivoBiome”, footwear is digitally manufactured and 3D printed using a radical scan-to-print circular footwear system. They’re made to measure, made to order and made to be repurposed. Using one’s footprint to formulate a design blueprint, shoes are made to fit each individual perfectly, eliminating wastage and improving longevity and wear.

Is 3D Printed Footwear Stylish Enough to Hit the Mainstream?

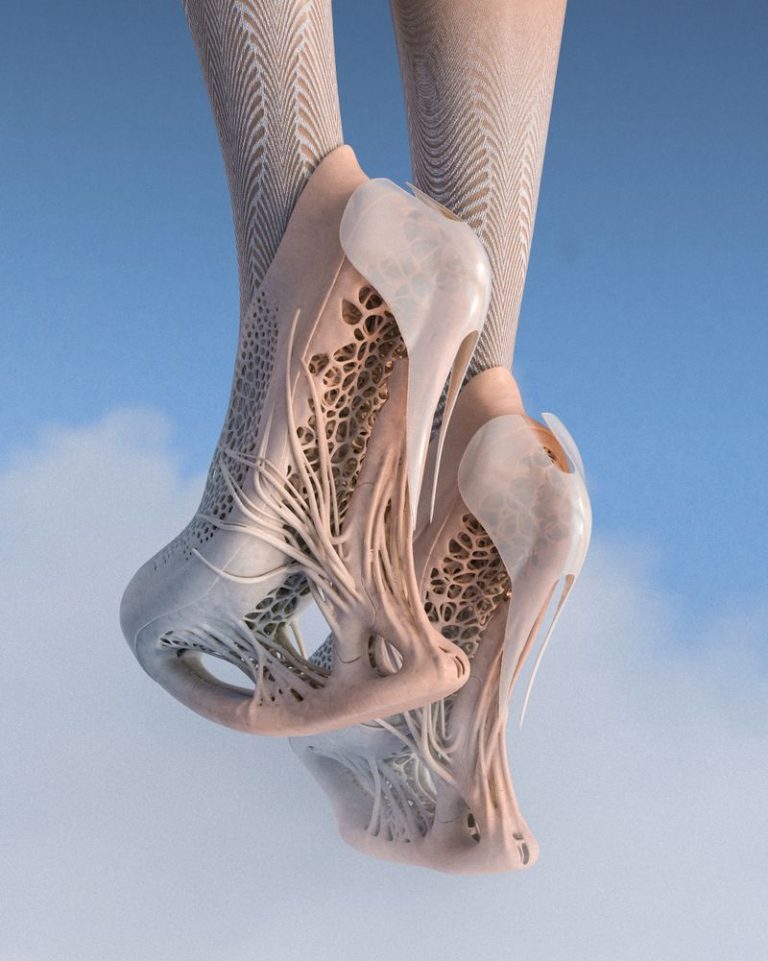

If it isn’t visually appealing, it just won’t sell. With this in mind, the creative minds behind 3D printed shoes are constantly experimenting, creating endless digital iterations and consistently pushing the boundaries of design. Stephan Henrich and SCRY Lab are two of the 3D printing prodigies that have caught our attention at GLITCH, presenting ideas that prompt us to explore, imagine and inquire. Just last year, Henrich was awarded overall winner at the Global Footwear Awards for his design entitled, “THE CRYPTIDE”, inspired by mythical creatures like Bigfoot. SCRY, founded in 2020, fuses art, design, technology and culture to bring cutting-edge creations to life. Coined the “Digital Embryo”, the team at SCRY Lab use a unique structure of digital design and manufacturing process. This structure led to the creation of SCRY Shuttle, “the world’s first pair of integrated additive manufacturing footwear that is actually wearable”.

While there is still much to learn and explore with this technology, it clearly holds a firm place in building a more sustainable future in fashion.

Written by Ashley Jade Callahan from GLITCH Magazine